Setting up orders. Types of brickwork, exterior walls, ordering. Prices for ready-made furnaces for brick ovens

K category: Brickwork

Types of orders, their installation

Orders are devices made of corners, pipes or slats with divisions corresponding to the thickness of the horizontal rows of masonry (77 mm for single and 100 mm for thickened bricks). They are designed to secure the mooring cord and ensure the verticality and horizontality of the rows of laid out walls.

A variety of ordering designs are classified according to several criteria.

Corner metal orders act as a template, which, when properly installed and rigidly fixed, ensures the verticality of the masonry. Fix the orders with brackets with screw clamps or hooks. The mooring cord is attached to a mobile collar or to holes in order. To remove the order, use a rail-rule with a hole at the end.

Intermediate wooden orders are clamped with U-shaped brackets inserted through 6-8 rows into the masonry seams and fixed with wedges.

The orders are set before the start of laying at the corners of the building, at the junction of the walls, and on long sections - every 12 m.

First, one clamp is fixed in the vertical seam of the masonry, and after 3-4 rows, another. Then, an order is inserted between the installed clamps and a screw clamp is pressed against the masonry. The screws at the lower end of the order adjust its vertical position. The correctness of the installation is controlled by a plumb line. After reconciliation between the orders, the mooring cord is pulled.

Rice. 1. Self-tightening grip 1 - grip frame; 2 - tension plates; 3 - clamping beams; 4 - gripper

Rice. 2. Tank for wetting bricks 1 - loop; 2 - runs

Rice. 3. Portable lamp 1 - sliding frame; 2 - telescopic stand: 3 - wire 4 - phone

Rice. 4. Metal container

1 - loop; 2 - double door

Rice. 5. Tubular ordering 1 - the fixed part of the clamp; 2 - squeezing screw; 3 - the movable part of the clamp; 4 - rack; 5 - slider with clamping bracket; 6 - mooring cord

Rice. 6. Angular and intermediate orders

Rice. 7. Placement of corner (a) and intermediate (b) orders a - metal for outer corners; b - the same for internal; in - metal with brackets; g - wooden intermediate; 1 - hook-holders; 2 - holes for fixing the mooring line; 3 - bracket with screw clamp; 4 - “P”-shaped bracket; 5 - wooden wedge

Rice. 8. Installation and alignment of the order 1 - adjusting screws; 2 - fixing clamp; 3 - screw clamp; 4 - mobile clamp with a mooring; 5 - plumb

The laying of the outer verst is carried out along the pier stretched for each row. To prevent the mooring line from sagging, an intermediate beacon is placed under it.

For laying the inner verst, the mooring is pulled at least every 2-3 rows and fixed with staples or nails.

The orders are removed with the help of a rule put on the collar of the screw clamp of the clamp. By rotating the knob, the clamp is loosened and removed from the seam. To prevent the clamps from falling down, they are attached with a steel rope to the order.

The use of orders reduces the time for checking the correctness of the laying, ensures the verticality of the corners and the required thickness of the horizontal joints.

- Types of orders, their installation

Brick is an excellent material that has been used in construction since ancient times. But its successful use largely depends on the quality of the masonry. In order for the brickwork to be even, a special device is used - ordering.

Ordering is a rail with divisions, which serves as a template for even, high-quality masonry.

Ordering can be made at the factory, but you can also assemble it yourself, observing the basic design principles. It helps to control the vertical and horizon level when laying bricks, speeds up work, since it takes less time to check.

As a rule, the order is made from a metal corner or wood. The corner is taken with a size of 60x60 millimeters, and wooden slats - with a section of 5x5 centimeters. Divisions are applied to the vertical racks of the order, according to the thickness of the brick, taking into account the width of the seams, this is approximately 77 millimeters for ordinary bricks (65 millimeters is the thickness of the brick, plus 12 millimeters for the seams) and 100 millimeters for thickened bricks (88 + 12). If a brick of a different size is used, then the distance between the divisions will be different.

The divisions can be marked with serif marks or slots, which are also used to stretch the mooring cord. It will indicate the horizon of the masonry and the cord for vertical correction. The mooring cord is located at the level of the top of the brick in the row, each row of masonry is equal to it. Ordering can be from 1 to 5 meters long. It is used in the construction of various objects: walls, fences, stoves, etc.

For the convenience of work, the order is set from the outside, by divisions inward, so that the bricklayer can navigate along them during the laying process.

Ordering from a metal profile is placed at the corners of a building or structure and fastened to clamps. The end of the clamp is hammered into the seam, the screw is clamped. The second clamp is installed in the same way several rows higher. After laying the tier, the ordering is rearranged to the upper clamp, and the lower one moves to the height of the next tier. It is better to clean the order from the solution before each move.

Intermediate orders are mounted on straight walls with a difference of 10-12 meters. They are mounted on U-shaped metal brackets, equipped with a transverse bar. The part is placed in the seam horizontally through 5-7 rows of masonry. Staples are placed one above the other, deepening the ends and the transverse bar into the seam. When installing, it is important to check the verticality of the order with a plumb line. The location of the marks (serifs or holes) is checked by the level. When all the parameters are verified, you can finally fix the order and pull the mooring cord. To prevent the cord from sagging on the longest sections of the wall, an intermediate beacon is placed under it, on which the cord rests.

As you move up, the mooring cord moves to the top level of each new row with an indent from the wall plane of approximately 3 millimeters. At the borders and at the corners of the walls, a beacon is laid out - a secure penalty. It will not only simplify further work, but also allow you to take a break.

Sheer lines are made 6 rows in height and are used to fasten the mooring line. Sheer shtraba is a laying method in which bricks are laid in a "ladder" with a difference of half a brick. It helps to make the ligation more reliable. It is used to secure the mooring cord and connect masonry sections. Such a penalty is especially useful when you need to build an even partition between walls. The mooring at the lighthouses is fixed with staples every 5 meters or fastened to a nail inserted into the seam.

When all the orders are set and the cords are taut, you need to check them again with a level and a plumb line. Further adjustments can be made using brackets and beacons. When working indoors, instead of ordering, as a rule, mooring brackets are used. The lower end of the bracket is inserted into the masonry seam, and the other should rest on the lighthouse brick. It is to this part that the mooring cord is attached. The second end is attached to the lighthouse brick on the other side of the masonry. The mooring cord must pass from the bracket to the upper plane of the lighthouse brick.

These designs are placed with a frequency in several rows. It is allowed to work in places where it is impossible to establish order. Brick masonry can be full or hollow. For each type of brick, a different solution is used. But in any case, it should not be too liquid, otherwise its consumption will increase dramatically. For laying bricks, you will need an order with a mooring cord, a plumb line, a trowel, a pick, a level, a joint.

Ordering allows not only to simplify the laying work, but also guarantees the construction of a smooth wall throughout. Although building more than six rows at a time, only a bricklayer with extensive experience can.

The brick is made in the form of a rectangular parallelepiped with the following dimensions:

The brick has 6 surfaces: 2 poke, 2 spoon and 2 beds.

Designation of brickwork elements

To make this article more informative for you, you need to understand the simple terms inherent in brickwork, the definition of which is presented below.

Brick laying is carried out in horizontal rows. Bricks are laid on the mortar with a wide edge - a bed (there are ways to lay on spoons).

Horizontal seam- a seam between adjacent horizontal rows.

vertical seam- a seam separating the side faces of adjoining bricks. There are transverse and longitudinal.

Inner verst- a row of brickwork that goes to the inner surface.

Front or outer verst- a row of masonry that goes to the outer (facade) side.

Zabutka- rows located between the inner and outer versts.

Spoon row- a row of bricks, which are laid with spoons to the surface of the wall, i.e. long edges.

Tychkovy row- a row of bricks, which are laid with pokes to the surface of the wall, i.e. short edges.

Suture dressing system- a certain order of alternation of spoon and tychkovy rows.

Spoon masonry- masonry, in which the brick is laid with a spoon outward in relation to the front surface of the wall.

bonded masonry- masonry, in which the brick is placed with a poke outward in relation to the front side of the wall.

The width of the brickwork must be a multiple of an odd or even number of halves (1/2) of the brick.

Thickness of brickwork

Depending on climatic conditions, the purpose of the structure and design loads, brickwork can be of the following thickness:

Masonry thickness = total thickness of bricks in masonry + mortar thickness between bricks. An example of laying in 2 bricks: 250 mm + 10mm + 250mm = 510mm

The width of the vertical joint in brickwork when planning dimensions is considered to be 10 mm, but in practice this number varies from 8 to 12 mm.

Masonry in a quarter brick (1/4) - 65 mm

Half-brick laying (1/2) - 120 mm

Masonry in one brick - 250mm

Laying in one and a half bricks (1.5) - 380mm (250 + 10 + 120mm)

Masonry in two bricks - 510 mm (250+10+250mm)

Masonry in two and a half bricks (2.5) - 640 mm (250 + 10 + 250 + 10 + 120mm)

In construction, they are most often used:

- single (ordinary, standard) brick, which has a height of 65 mm;

- thickened brick with a height of 88 mm.

The height of the horizontal seam in brickwork when planning the dimensions of the building is considered to be 12 mm, but in practice this number varies from 10 to 15 mm.

When electrical heating of brickwork or its reinforcement, electrodes or a metal mesh are placed in horizontal seams, respectively. In this case, the size of the seam should not be less than 12 mm.

Knowing from which brick (single or thickened) the structure is planned to be erected, you can easily calculate the height of the future structure:

| Number of rows of masonry | Construction height, mm | |

|---|---|---|

| single brick | thickened brick | |

1 row (height of 1 brick + |

77 (65+12) | 100 (88+12) |

2 rows (height 2 bricks + |

154 (65+12+65+12) | 200 (88+12+88+12) |

3 rows (height 3 bricks + |

231 (65+12+65+12+65+12) | 300 (88+12+88+12+88+12) |

4 rows (height 4 bricks + |

308 | 400 |

5 rows (height 5 bricks + |

385 | 500 |

6 rows (height 6 bricks + |

462 and further through 77 mm | 600 and further after 100 mm |

Height of 10 rows of thickened bricks = Height of 13 rows of single bricks = 1000 mm

In order not to calculate and bring the sketch dimensions to the constructive ones each time, the designer uses the brickwork size table. www.site

dressing systems

In order to combine rows of brickwork into a single solid monolithic structure, seam dressing systems are used. For theory, we suggest that you familiarize yourself with the basic rules of brickwork.

There are ligation of the following vertical seams:

- transverse,

- longitudinal.

The strength and reliability of brickwork largely depends on the quality of the dressing of vertical longitudinal and transverse seams.

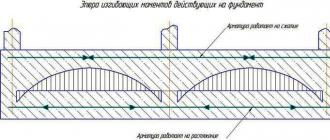

Ligation of vertical longitudinal seams is carried out by laying bonded rows and helps to avoid longitudinal destruction of the masonry.

Ligation of vertical transverse seams is performed by alternating spoon and bond rows, and in adjacent rows it is necessary to shift the bricks by a quarter or half. This dressing provides: uniform distribution of the load on the nearest sections of the masonry and the longitudinal interconnection of adjacent bricks, which in turn gives the brickwork solidity and strength with uneven temperature deformations and precipitation.

Suture dressing systems

In construction, the following joint dressing systems are most often used:

- single row or chain;

- multi-row;

- three-row.

Single row system (chain)

Single-row dressing of seams is performed by successive alternation of bonder and spoon rows in compliance with the following rules:

- The first (lower) and last (upper) rows are laid with pokes.

- Longitudinal seams in adjacent rows are shifted by 1/2 (half a brick) relative to each other, transverse - by 1/4 (a quarter of a brick).

- The bricks of the overlying row must necessarily overlap the vertical seams of the underlying row.

With a single-row dressing during the laying process, a large number of incomplete bricks (most often 3/4) will be needed, the cutting of which will entail not only labor costs, but also serious loss of bricks, which will ultimately lead to significant financial investments.

It must be remembered that the chain dressing system is the most labor-intensive, but despite this, it is also more durable and reliable.

Multi-row system

Multi-row ligation of seams is a brickwork laid out in spoon rows, which are tied up in height every 5-6 rows with one tying row. With this dressing system, the following rules must be observed:

- The first one, which is the bottom row, is placed with pokes.

- Second row - spoons.

- The third, fourth, fifth and sixth - with spoons with dressing of seams in 1/2 (half a brick). Do this regardless of the thickness of the wall.

- Along the width of the wall, the vertical longitudinal seams of the masonry of five rows do not need to be bandaged.

- The pokes of the seventh row overlap the seams of the sixth spoon row by 1/4 (a quarter of a brick).

Advantages of the multi-row dressing system:

- there is no need for a large number of incomplete bricks;

- most productive;

- allows the use of brick halves for masonry;

- improves the thermal performance of the masonry (this occurs due to increased thermal resistance, located along the path of the heat flow, not bandaged longitudinal seams of five rows).

Flaws:

- the third rule for cutting brickwork is not fully observed;

- strength is less than with single-row dressing;

- cannot be used when laying brick pillars due to incomplete dressing of the longitudinal seams.

Three row system

The three-row joint dressing system is used for brickwork of narrow walls and pillars, the width of which does not exceed 1 m.

The main types of suture dressing

Masonry in 1 brick (cross) - option 1

| View from the facade

|

Ligation of sutures

|

|

|

|

Masonry in 1 brick (cross) - option 2

| View from the facade

|

Ligation of sutures

|

| View from the facade. Dressing 2 and 3 rows of masonry

|

Inside view. Dressing 2 and 3 rows of masonry

|

Masonry in 1 brick multi-row

Masonry in 1.5 bricks option 1

View from the facade  |

Ligation of sutures

|

View from the facade. Dressing 2 and 3 rows of masonry  |

Inside view. Dressing 2 and 3 rows of masonry

|

Masonry in 1.5 bricks. Option 2

| View from the facade

|

Ligation of sutures

|

| View from the facade. Dressing 2 and 3 rows of masonry

|

Inside view. Dressing 2 and 3 rows of masonry

|

Masonry in 2 bricks

| View from the facade

|

Ligation of sutures

|

| View from the facade. Dressing 2 and 3 rows of masonry | Inside view. Dressing 2 and 3 rows of masonry

|

Masonry in 2.5 bricks

| View from the facade

|

Ligation of sutures

|

| View from the facade. Dressing 2 and 3 rows of masonry

|

Inside view. Dressing 2 and 3 rows of masonry

|

Masonry methods

Inner and outer versts are laid in the following ways:

- butt,

- end-to-end with cutting solution,

- hold on.

Zabutka is put in a semi-prisy way.

The choice of a particular method depends on:

- season,

- requirements for the cleanliness of the outer surface of the masonry,

- the condition of the brick itself (wet or dry),

- plasticity of the solution.

Masonry technology

Before you start the brickwork on the basement, it is necessary to carry out insulation. To do this, a layer of roofing material or other insulating material is laid around the perimeter of the masonry under the brick.

With the help of a level, several rows of bricks are laid at the corners of the basement. Orders are attached to the corners with brackets. The distance between the divisions in the order is 77 mm (65 mm single brick height + 12 mm mortar height). According to the established orders, mooring cords are pulled, which help to maintain the straightness and horizontality of the erected rows of brickwork. It is advisable to place the cord every 5 m to prevent it from sagging (if the mooring is stretched over 10 m, then after 5 m a beacon is made in the form of bricks to tension the cord). The mooring cord for the outer wall is fastened in order, and for the inner wall with brackets.

On a brick, using a trowel, put a solution, a thickness of 30 mm and an indent from the outer part of the wall - 20 mm. The first row of brickwork is bonded. The brick is laid in the "press" or "butt" method.

Butt method

Using the “butt-on” method, the brick is laid on a plastic mortar (cone draft 12-13 cm).

The sequence of actions when laying bricks "back to back":

- At first:

- take a brick in hand and tilt it a little,

- they rake with a face (with a spoon - for the poke row, with a poke - for the spoon row) onto a brick with a little spread mortar,

- move the brick with the raked mortar to the brick that was laid earlier.

- Then the brick is deposited on the mortar.

Clamp method

Using the “press” method, the brick is laid on a hard mortar (cone draft 7 ... 9 cm) with mandatory jointing and complete filling of the seams.

The sequence of actions when laying bricks "press":

- To the vertical edge of the previously laid brick with a trowel, they rake up and press part of the mortar.

- Then a new brick is laid, be sure to press it against the trowel.

- With a sharp upward movement, the trowel is taken out.

- Planting a brick.

Stitching

To obtain sufficient compaction of the mortar in the seams, as well as to give the brickwork a clear pattern on the outside, jointing is used. In this case, bricklaying is performed with mortar trimming. When stitching, the seams are given the following forms:

- triangular

- concave

- convex

- rectangular

- rounded.

So, for example, to obtain convex seams, concave-shaped jointing is used.

To obtain better seams and reduce labor costs, the seams of brickwork are embroidered until the mortar sets, observing the following sequence:

- with a brush or rag, wipe the surface of the brickwork from mortar splashes adhering to it;

- embroider vertical seams (3-4 spoons or 6-8 poke);

- embroider horizontal seams.

If in the future you plan to plaster the walls, then the laying of bricks must be done in a waste, i.e. do not bring the mortar up to 10-15 mm to the wall surface. This method will allow the plaster to be firmly fixed on the wall surface. © www.site

Undercut  |

wasteland |

| Convex seam |

concave seam |

Single seam  |

Double seam  |

Brick walls. Laying methods.

The most reliable and practically unchanged walls for decades are those lined with bricks. The most proven - clay red and silicate white bricks.

The thickness of the walls in one-story houses is laid out in brick or half-brick. In the first case, no additional insulation materials are required, the house will be warm. In the second, it is necessary to use materials such as, for example, slabs of wood concrete or fiberboard. If the house is more than one floor, then the walls are laid out at least one and a half to two bricks.

For laying bricks, cement or cement-lime mortar is used. In order for the seams in the masonry to be several tones lighter than the standard, white cement is used, a mixture of hydraulic and quicklime mixture can be used.

Building solutions.

The solution is kneaded in specially prepared containers, which are usually made of plastic or tin.

Before starting masonry work, the brick must be sorted. Separately lay down a whole brick that does not contain chips or chips. Fragments of bricks (halves and three-quarters) and bricks with obvious defects are stacked nearby. A whole brick will go to that part of the wall that faces the street, a brick with small defects - to that side of the wall that will be facing the room, since after the completion of the masonry work it will be plastered. Halves and three-quarter bricks will be used for bonding in the masonry. In cases where a half or three-quarter has an uneven chipped surface, it is leveled with a pickaxe hammer. When there are no halves and three-quarters, and they are required for masonry, they cut a whole brick.

Methods for cutting hollow and solid bricks differ. A hollow brick is marked on all four sides of the proposed cutting line, then in places where voids are punched with a pickaxe hammer, then partitions are cut through with a chisel or chisel and only after that corners are cut. A solid brick is marked along the cutting line and the desired part is chipped off with a sharp blow with a pickaxe hammer.

The first row must be placed on the waterproofing layer. In order for the masonry to meet all the requirements, namely, the rows were strictly horizontal, and the wall itself was vertical, they use a mooring and ordering. Orders are attached to all corners of the building being erected, a mooring is tied to them. At the same time, make sure that the upper edge of the brick being laid fits exactly under the mooring (Fig. 10).

Rice. 10. Attachments for masonry: 1 - mooring; 2 - ordering

In order for the wall to turn out neat and have no deviations from the drawing, it would be more correct to adhere to the following algorithm: start a row with laying out miles without mortar with a gap of 10-20 mm in order and mooring, after which they proceed to the masonry itself on the mortar. The first brick in a verst is removed, a mortar is put in its place with a trowel, carefully leveling it. If the laying is carried out for jointing, then the amount of mortar is placed in such a way that when pressing on the brick and giving it the desired position, the mortar is squeezed out. Excess mortar is removed with a trowel, and after the row is completely finished, the seam is given an aesthetic appearance with the help of jointing.

In the case when the wall is laid under plaster, less mortar will be required, since when laying the mortar, so much is applied so that when the brick is given the desired position, the mortar not only does not squeeze out, does not reach the edges of the brick by 10-12 mm. This type of masonry is called wasteland, the thickness of the seam can vary from 1 to 3 cm, which is convenient for plastering.

A second brick is placed to the first brick so that the bricks are filled with mortar between the ends, then the third, fourth and so on.

All rows of masonry are carried out along the pier, which moves as the masonry rises.

Another way of leveling the masonry has also proven itself, namely with the help of formwork. To do this, racks with notches are firmly attached to both sides of the wall, which show the height of the row, while notches with the number “one” should be on the same level for all racks, all with the number “two” are also on the same level, and so on for all numbers, which guarantees the horizontality of each masonry row. At the level of the notches at the distance of the masonry row, two even edged boards are nailed, along which the masonry is carried out, then the boards are interrupted one row higher and so on.

All masonry is carried out with dressing, in which the bricks of the second row overlap the joints of the bricks of the first row, the third row is laid in the same way as the first, the fourth in the same way as the second, continuing this alternation as the wall is laid. This type of masonry gives not only an aesthetic appearance to the structure, but also evenly distributes the load throughout the wall.

A row laid out on a wall with a brick reproach is called a poke, and the one that is along is called a spoon. The outer row in the wall is called a verst, the inner row is called a backfill.

For a bricklayer with little work experience, it is more convenient to carry out masonry when there are three to five spoon rows for each row of rows (Fig. 12, 13).

If single-row masonry is carried out, the spoon and bonder rows alternate.

To save on bricks, you can lay out the so-called hollow walls, be sure to follow the masonry technology during such work (Fig. 14). The wall is obtained in half a brick, five or six bricks in a row between the transverse lintels. For reliability, some seams can be fastened with a metal mesh. All cavities are filled with dried bulk insulation, and lightweight concrete is also allowed. Each row wakes up before the start of laying with jumpers of the next row (Fig. 15).

To save on bricks, you can lay out the so-called hollow walls, be sure to follow the masonry technology during such work (Fig. 14). The wall is obtained in half a brick, five or six bricks in a row between the transverse lintels. For reliability, some seams can be fastened with a metal mesh. All cavities are filled with dried bulk insulation, and lightweight concrete is also allowed. Each row wakes up before the start of laying with jumpers of the next row (Fig. 15).

In order not to gouge holes in the built wall, it is better to determine in advance where the communications will go and leave holes of appropriate sizes in these places.

In order not to gouge holes in the built wall, it is better to determine in advance where the communications will go and leave holes of appropriate sizes in these places.

In the openings where doors and windows will be placed, wooden corks are inserted at the required heights. Corks, which should have the size of a brick, must be treated with an antiseptic and wrapped with roofing material. Six plugs should be installed on the door, four on the window.

Jumpers are provided above the openings. Ordinary jumpers are made of round or flat rods, placing them every 13 cm. The jumpers are poured with a solution 3-4 cm thick. The free ends of the rod 12 cm long are bent up for anchoring into vertical seams.

Above the future window or door, concrete or wooden lintels are used. Lintels made of wood must be at least 5 cm thick and treated with an antiseptic, the edges that will be recessed in the masonry are wrapped in roofing material or roofing felt. Reinforced concrete lintels are used factory-made, or our own production. For independent production of a concrete lintel, rods from 4 to 6 mm in cross section and a length of 8-10 cm more than the width of the opening, concrete, the grade of which must be at least 100, and timber formwork, are required.

Reinforced concrete lintels can be made both at the opening site and made from in advance. In both cases, the reinforcement is connected to each other with a wire in the form of a frame, which is placed in the formwork, so that it is 3-4 cm from the bottom, for this you can put in two places of the frame, for example, wooden blocks of the right size. From above, the frame must be filled with a solution of at least 7 cm. The length of the jumper is made 25 cm more than the opening.

With hollow masonry, the following brick consumption is assumed:

Brick standard size. There are 36 bricks for one m² of masonry, 48 bricks against the usual half-brick masonry, 96 bricks for brick.

Modular brick. The ratio is 36 bricks versus 40 and 80.

As you can see, modular and standard bricks go the same way.

Paired ventilation holes are left in the hollow masonry under the floor and ceiling in each room.

| Look at the website | |||

Trowel type KB

Each work operation has its own tool or device, the main ones are a mortar shovel, trowel, jointing and a pickaxe hammer.

Trowel for stone work (GOST 9533-81) is a steel spatula polished on both sides with a wooden handle, used for leveling on masonry, trimming excess mortar in the seams, filling vertical joints with mortar.

Trowel type KB

Trowel type KP

Mortar shovel LR

The estimated cost of the trowel is 50-80 rubles.

mortar shovel(GOST 19596-87) is used for supplying the solution, as well as spreading it on the wall; mixing the solution in the box: leveling the solution between versts under the backfill.

Estimated cost - from 100 rubles.

Joints convex and concave- designed to process seams and give them a certain shape. Depending on the required thickness and shape of the seams, both the cross-sectional profile and the size of the joint are selected. The cost is about 50 rubles.

Jointing for seams curved

Jointing for seams curved

Jointing for seams concave

Pickhammer necessary for tesky and cutting a whole brick into incomplete ones. The cost of a pickaxe hammer is from 150 rubles.

Pickhammer

mop

mop used when cleaning ventilation from the solution that has come out of the seams; for a more complete filling of the joints with mortar, as well as smoothing the joints. At the bottom of the tool handle, between the flanges, a rubber plate measuring 140x140x10 (12) mm is fixed, which is the working part.

Control and measuring tools for laying bricks.

plumb line designed to control the verticality of walls, pillars, walls and masonry corners. The measurement process is hanging masonry. plumb lines

A mass of 200-400 g is used to control the correctness of the brickwork in tiers within the height of the floor; weighing 600-1000 g - to control the outer corners within the height of several floors.

Building level serves to check the verticality and horizontality of the masonry. The body of the level is made of aluminum alloy, length

housings 300/500/700 mm, etc. Glass tubes-ampoules are installed on the body. The ampoules are not completely filled with antifreeze liquid, and an air bubble remains in them. The measurement of the horizontal/vertical deviation is set by the deviation of the air bubbles from the middle position.

Building level

Pravi'lo- a wooden lath with a section of 30x80 mm, 1.5-2 m long, as an option - a duralumin lath 1.2 m long. The rule is designed to check the front surface of the masonry.

Cord-mooring– twisted cord 3 mm thick. When laying versts, the cord-mooring is pulled between the orders and lighthouses. It is used in the bricklaying process as a guideline to ensure that the rows of masonry are straight and level, and that the horizontal joints are of uniform thickness. With its help, they determine the position that each laid brick in a verst should have.

Cord-mooring

Cord-mooring

Wooden ordering- a rail with a section of 50x50 mm or 70x50 mm, up to 2 m long. Divisions (serifs) are marked on the order every 77 mm, which corresponds to the thickness of the masonry row (65 mm brick thickness + 12 mm joint thickness), as well as 100 mm for thickened brick (88 + 12 mm). Orders are used for marking rows of masonry, as well as fixing marks for the bottom and top of door and window openings, runs of floor slabs, lintels, etc.

ordering

The order is established so that the sides on which the rows of masonry are marked are facing the bricklayer, they are fixed in the masonry with U-shaped steel holders (bracket with a transverse bar). Staples-holders are introduced in height every 6-8 rows along the masonry, placing one above the other. The brackets must enter the wall with the ends and the cross bar. After laying 1-2 rows of bricks on the second holder, the order is inserted into the brackets, securing it with wedges. A mooring cord is moored to the orders, installing with a double bracket. The cord is attached to the initial part of the bracket. They remove the order along with the holders, without removing the wedges.