Metrology objects concept characteristic. Subjects of metrology. Objects and subjects of metrology. The main centers of standards are

Objects and subjects of metrology

Questions:

- Metrology objects. Quantities, their classification and characteristics

- Classification of physical quantities and their units

- Measurement types

- Subjects of metrology, their classification and brief characteristics- Practical work

1. Objects of metrology: quantities, their classification and characteristics

The main objects of metrology are quantities and measurements.

The magnitude - a property of the measured object, which is qualitatively common for all objects of the same name, but individual - quantitatively.

Quantities are subdivided into physical and non-physical.

Physical quantity -one of the properties of a physical object (physical system, phenomenon or process), qualitatively common to many physical objects, but quantitatively individual for each of them

Non-physical quantities- the properties of economic, psychological and similar objects, not related to physical objects. Their measurement is carried out indirectly, through physical quantities.

For example, an economic characteristic - price - has a monetary expression relative to certain units of measurement (kilogram, meter, etc.). Such a psychological property of a person as the speed of reaction is expressed in units of time (for example, the time for making decisions).

For a long time it was believed that only physical quantities can be objects of metrology. Recently, however, it became necessary to measure non-physical quantities, mainly through physical quantities. Thus, the scope of application of metrology has expanded significantly.

At the same time, it should be noted that some authors (MN Selivanov, IM Lifits) believe that it is expedient to apply the term not “measurement” to non-physical quantities, but “estimation”. At the same time, only the term “measurement” is used in the new OEI Federal Law.

From the definition of the term "quantity" it follows that it has two characteristics: qualitative, or dimension defined as a name, and quantitative, or size , defined as the value of the measured quantity.

Obtaining information about the size of a physical and non-physical quantity is the goal and end result of any measurement.

The set of names of physical quantities and units of their measurements aremeasurement system.

The values of the measured quantities, as noted, are individual and to a certain extent random, which is due tothe basic tenet of metrology: "Any count is random."

Despite this, in metrology, it is customary to distinguish between the following values of physical quantities: true, real and the result of observation.

The true value of physical quantities- a value that would ideally reflect the corresponding physical quantity in qualitative and quantitative terms.

Actual value of physical quantities- the value of physical quantities found experimentally and so close to the true value that it can replace it for a given measuring task.

Observation result- a single actually measured value of physical quantities.

The values of physical quantities are expressed in established, accepted units of measurement.

Unit of magnitude- a fixed value of a quantity, which is taken as a unit of a given quantity and is used to quantify quantities that are homogeneous with it.

Measurement of a specific physical quantity is made by comparing it with the value taken as a unit of this quantity. The result of the measurement will be a certain number showing the ratio of the measured value to the unit of the physical quantity.

2. Classification of physical quantities and units of their change

The classification of units of measurement of physical quantities is shown in Fig. 2.2.

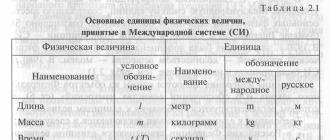

Basic physical quantity- a value conventionally taken as independent of other physical quantities. An example of a basic physical quantity is length, mass, etc. (Table 2.1).

Basic physical quantityis a physical quantity included in the system of quantities and conventionally taken as independent of other quantities of this system (Table 2.1).

Derived physical quantity- a physical quantity determined through the basic quantities of this system. Derived quantities include volume, area, speed of movement, relative density, etc.

Derived unit of physical quantity- a unit of a derived physical quantity. Derived physical quantities can be obtained from the same or opposite physical quantities. An example of quantities of the same name can be fractional units of the mass of a gram, milligram, or multiples - ton (t), centner (c), and opposite ones - meter per second (m / s), gram per cubic decimeter (g / dm3), etc.

System of units of physical quantities -a set of basic and derived units of physical quantities, formed in accordance with the principles for a given system of physical quantities.

The first system of units of physical quantities was the metric system, in which at first there were two basic units: meter - a unit of length and gram - a unit of weight. The metric system was first adopted in France (1840), then in Germany (1849). Later it was admitted along with national systems in Great Britain (1864), USA (1866), Russia (1899). However, along with the metric system in other countries, national, historically developed systems were used, which are still used today. For example, in the UK, USA and Canada, units are still used that do not have an integer decimal ratio with the metric system.

In 1960, the XI General Conference on Weights and Measures approved the International System of Units, containing six basic physical quantities and abbreviated SI , in Russian transcription - SI. In 1970, this system was supplemented by the seventh basic physical unit - the amount of matter - the mole. In 1980, SI was adopted in our country. (see table 2.1).

Units of measurement are one of the objects of the OEI Federal Law (Art. 6), which regulates the requirements for units of quantities. (write off yourself)

The unit requirements are as follows:

- in the Russian Federation, SI units are used, adopted by the General Conference on Weights and Measures (GMKV) and recommended for use by the International Organization of Legal Metrology. The Government of the Russian Federation may allow non-systemic units of quantities to be used in the Russian Federation on a par with SI units. The names of the units of quantities allowed for use in the Russian Federation, their designations, the rules of writing, as well as the rules for their application are established by the Government of the Russian Federation;

- characteristics and parameters of products supplied for export, including measuring instruments, can be expressed in units of quantities stipulated by the agreement (contract) concluded with the customer;

- units of quantities are transferred to measuring instruments, technical systems and devices with measuring functions from the standards of units of quantities and standard samples.

In Russia, off-system units of measurement are, for example, degrees Celsius and kilocalorie along with kelvin and joule.

In accordance with the decisions of the General Conference on Weights and Measures (GCMW) adopted in different years, the following definitions of the basic SI units are in force.

Unit of length - meter - the length of the path traveled by light in a vacuum in 1/299792458 fractions of a second.

Unit of mass - kilogram - the mass equal to the mass of the international prototype of the kilogram.

Time unit - second - the duration of 9192631770 periods of radiation, corresponding to the transition between two hyperfine levels of the ground state of the cesium-133 atom, not perturbed by external fields.

Electric current unit- ampere - the strength of a constant current, which, when passing through two parallel conductors of infinite length and negligible circular cross-section, located at a distance of 1 m from one another in a vacuum, would create a force between these conductors equal to 2 10-7 N for each meter length.

Thermodynamic temperature unit- kelvin - 1 / 273.16 of the thermodynamic temperature of the triple point of water. Expression of thermodynamic temperature in degrees Celsius is allowed.

Unit of the amount of substance- mole - the amount of substance in a system containing the same number of structural elements as atoms are contained in a carbohydrate-12 nuclide weighing 0.012 kg.

The unit of luminous intensity - candela - is the luminous intensity in a given direction of a source emitting monochromatic radiation with a frequency of 540 · 1012 Hz, the luminous intensity of which in this direction is 1/683 W / sr.

As noted, along with the SI system units, the use of non-SI units is allowed. An example of off-system mass units that are derived from the kilogram are ton, centner, pood, carat, spool, etc.

Derived units of physical quantities are subdivided into systemic and non-systemic ones, and in relation to basic units - into multiples and fractional ones.

A multiple unit of a physical quantity is a unit of a physical quantity that is an integer number of times greater than a system or non-system unit.

Fractional unit of a physical quantity - a unit of a physical quantity that is an integer number of times less than a systemic or non-systemic unit.

An example of a multiple unit of length for a basic unit - a meter - is a kilometer, and a fractional unit is a millimeter, centimeter, decimeter.

For the convenience of using units of physical quantities, prefixes are adopted for the formation of multiples and sub-multiples, for example, deci, centi, etc.

Practical work on units There to write off tables from Sergeev p. 21-29)

3. Types of measurements

Measurements are divided into types according to certain classification criteria (Fig. 2.3):

1) by the method of obtaining information- on direct, indirect, aggregate and joint.

Direct measurements- measurements in which the desired value of the quantity is obtained directly from the measuring instrument, for example, measuring the length with a ruler.

Indirect measurements- measurements in which the desired value of the quantity is determined on the basis of direct measurements of other physical quantities associated with the desired quantity with a known functional dependence, and the calculation of the first through the latter. For example, the starch content of potatoes and the salt content in brine is determined by the relative density of the tubers or brine.

Aggregate measurements- measurements, in which the actual values of several homogeneous quantities are determined, and the real value of the desired quantity is established by solving a system of equations.

The number of equations in the system must be less than the number of desired quantities. Aggregate measurements are a sophisticated form of direct measurements. For example, when determining the volume of an object, three lengths are measured: length (L), width ( d) and height (h ), while the volume is found by the formula V = Ldh.

Joint measurements- measurements, in which the actual values of inhomogeneous quantities are established in order to find the relationship between them. Joint measurements are a kind of indirect measurements. Common measurements are often used to determine coefficients. For example, the load factor of a warehouse is calculated by measuring the mass of goods and the usable storage area they occupy;

2) by the nature of the measurement of the information received during the measurement- for static, dynamic and statistical.

Static measurements- measurements that are carried out with the practical constancy of the desired value, for example, the measurement of the mass of a metal object. Those. if the characteristics of random processes are determined, then the measurements are called static and they can only be determined by multiple measurements.

Dynamic measurements- measurements, during which the sought value changes over time. For example, when measuring the mass of a ground wet sample of a product, the mass decreases due to constant evaporation of water.

Statistical measurements- measurements related to the determination of the characteristics of random processes, noise signals, etc., for example, measuring the mass of defective products during the final control at the manufacturer;

3) by the amount of measurement information - for single and multiple.

Single measurements- measurements in which the number of measurements is equal to the number of measured values. In practice, it is recommended to consider the averaged result of at least two to three measurements as one-time. The disadvantage of single measurements is the possibility of gross, unremovable errors.

Multiple measurements - measurements in which the number of measurements ( n ) exceeds the number of measured values ( m ). Usually in practice n> 3.

The purpose of multiple measurements is to reduce the influence of random errors on the measurement result;

4) in relation to the basic units in absolute and relative.

Absolute measurements- measurements in which the result is based on direct measurements of one or more basic physical quantities, for example, measurement of length, area, volume, etc.

Relative measurements- measurements in which the actual value of the desired quantity is established as the ratio of one quantity to another homogeneous or inhomogeneous quantity. For example, the relative density of an object is defined as the ratio of mass to volume.

When measuring, the size or quantitative characteristic of a physical quantity is determined. However, in a number of cases, it becomes necessary to determine only the dimension, the physical quantity, that is, its qualitative characteristics, for example, the acidity (pH) of the medium, the presence of an electric current or some substance in a multicomponent medium. In such cases, detection is used.

Detection - establishing the quality characteristics of the desired physical quantity. Units are not set on detection, but zero on detection confirms the absence of a physical quantity. For example, when an electric current is detected in the network, the device can record its absence.

Detection tools are most often indicators such as an electric current indicator; chemical indicators fixing the presence of certain substances in solutions (phenolphthalein and methyl orange are used for detection in alkali solution; Tillmans reagent - ascorbic acid, etc.).

Thus, detection can be considered as a kind of measurement of physical quantities related to its qualitative characteristics.

Requirements for measurements are established in the OEI Federal Law (Article 5) Write off independently:

- measurements related to the scope of state regulation of OEI must be carried out according to certified measurement procedures (methods), with the exception of measurement procedures (methods) intended for direct measurements, using an approved type of measuring instruments that have passed verification. Measurement results should be expressed in units of values approved for use in the Russian Federation;

- measurement techniques (methods) intended for performing direct measurements are included in the operational documentation for measuring instruments. Confirmation of the conformity of these measurement techniques (methods) to the mandatory metrological requirements for measurements is carried out in the process of approving the types of these measuring instruments. In other cases, confirmation of compliance of measurement procedures (methods) with mandatory metrological requirements for measurements is carried out by attestation of measurement procedures (methods). Information about the certified measurement techniques (methods) is transferred to the Federal Information Fund for OEI by legal entities and individual entrepreneurs conducting certification;

- certification of measurement techniques (methods) related to the sphere of state regulation of the OEI is carried out by legal entities and individual entrepreneurs accredited in the established order in the field of OEI;

- the procedure for attestation of measurement techniques (methods) and their application is established by the federal executive body in charge of developing state policy and legal regulation in the field of OIE;

- federal executive bodies that carry out legal regulation in regulated areas of activity determine measurements related to the sphere of state regulation of the OEI, and establish mandatory metrological requirements for them, including measurement accuracy indicators;

- The federal executive body responsible for the provision of state services and management of state property in the area of OEI maintains a single list of measurements related to the area of state regulation of the OEI.

4. Subjects of metrology- legal entities and individuals carrying out metrological activities. These include international and regional metrology organizations, as well as metrological services (government and legal entities).

Metrological service- organizing and / or performing work and / or providing services for OEI a structural subdivision of the central office of a federal executive body and / or its territorial body, a legal entity or a structural subdivision of a legal entity or an association of legal entities, employees of a legal entity, an individual entrepreneur.

There are three levels of subjects of metrology: international, regional and national (Fig. 24).

The international level is represented by international metrological organizations, which include representatives of national metrology organizations, and the regional level is represented by metrological organizations of the countries of a certain region of the globe.

The national level of metrology has two sublevels: state; services of legal entities. The state sublevel of metrology includes Rostekhregulirovanie, scientific metrological centers (NMC) and centers of standardization and metrology (CSM). Each group of subjects of the national sub-level has certain functions and areas of competence,

Rostekhregulirovanie(Federal Service for Technical Regulation and Metrology) carries out the state administration of the OEI. His competence includes:

- submission to the Government of the Russian Federation of proposals on units of quantities allowed for use;

- establishment of rules for the creation, approval, storage and use of measurement standards of units of quantities;

- determination of general metrological requirements for instruments, methods and results of measurements;

- implementation of state metrological control and supervision;

- monitoring compliance with the terms of international treaties of the Russian Federation on the recognition of test results and verification of measuring instruments;

- management of the activities of the State Metrological Service and other state services of the OEI;

- participation in the activities of international organizations on OEI issues.

State Metrological Serviceis under the jurisdiction of Rostekhregulirovanie and includes: state scientific metrological centers (GNMC); bodies of the State Metrological Service in the regions of Russia.

GNMC presented by the State Service for Time, Frequency and Determination of the Earth's Rotation Parameters (GSSVCH), the State Service for Standard Samples, Composition and Properties of Substances and Materials (GSSO) and the State Service for Standard Reference Data on Physical Constants and Properties of Substances and Materials (GSSSD). The management and coordination of their activities is carried out by Rostekhregulirovanie.

GNMC are responsible for the creation, improvement, storage and application of state measurement standards of units of quantities, as well as for the development of regulatory documents for the OEI

The bodies of the State Metrological Service include FMCs that carry out state metrological control and supervision in all regions of Russia.

Metrological service of legal entitiesrepresented by the metrological services of federal government bodies and enterprises (SMEs) that are legal entities (FZ OEI). Metrological services in state governing bodies and at enterprises are created, if necessary, in the prescribed manner to carry out work to ensure the uniformity and required accuracy of measurements, as well as to carry out metrological control and supervision. When performing work in areas where verification of measuring instruments is necessary, the creation of metrological services and other organizational structures for the OEI is mandatory.

Metrological services of legal entities carry out metrological control by calibrating measuring instruments, supervising the condition and use of measuring instruments, certified measurement techniques, standards of units of quantities used for calibrating measuring instruments, as well as observing the established metrological rules and norms. In addition, they check the timeliness of the submission of measuring instruments for testing in order to approve the type of measuring instruments, as well as for verification and calibration.

1. Objects of metrology - quantities, their characteristics

2. Classification of physical quantities and units of their measurement.

International System (SI).

3. Subjects metrology, their classification and brief description.

4. International and regional metrological organizations.

The main object metrology are magnitudes which are subdivided into physical and non-physical .

The magnitude- a property of the measured object, qualitatively common for all objects of the same name, but individual in quantitative terms. ... So, all physical bodies have mass, length, temperature, but each of them has different sizes of these physical quantities.

Physical quantities- properties of physical objects.

Non-physical quantities~ properties of economic, psychological, similar objects, not related to physical objects.

For a long time it was believed that only physical quantities can be objects of metrology. Recently, however, it became necessary to measure non-physical quantities, mainly indirectly, through physical quantities. Thus, the scope of application of metrology has expanded significantly.

Quantity follows from the definition of the term. That it has 2 characteristics - quality or dimension defined as Name , and quantitative or the size defined as measured value ... PV values are expressed in certain accepted units of measurement. Physical unit Is a physical quantity used to quantify homogeneous PV, which, by definition, is assigned a numerical value equal to (or is the size of a physical quantity, which, by definition, is assigned a value equal to one)

Measurement of a specific physical quantity is made by comparing it with the value taken as a unit of this quantity. The measurement result will be a certain number showing the ratio measured value with PV unit.

The values of the measured quantities are individual and to a certain extent random, which is due to the basic tenet of metrology : "Any count is random."

The set of names of physical quantities and units of their measurements make up the system... In the system of units of physical quantities, there are basic units of the system of units(in SI - meter, kilogram, second, ampere, kelvin). From a combination of basic units, derived units(speed - m / s, density - kg / m 3).

Classification of units of measurement of physical quantities

The main EF - EF, conventionally taken as independent of other EF.

Basic unit PV- the unit of the basic PV in the given system of units.

FV derivative- PV, determined through the basic values of this system.

Derived unit PV is a unit of PV derivative. The derivatives of PV can be obtained from the same or opposite PV.

Fw system is a set of interrelated basic and derived units of physical quantities.

The first system of units of physical quantities was Metric

a system in which initially there were two basic units: meter - the basic unit of length and gram - a unit of weight. The metric system was first adopted in France (1840), then in Germany), the USA ((1849), and then admitted along with the national systems in Great Britain (1864), in the USA (1966), in Russia (1899). the metric system in other countries also used national, historically developed systems that are still in use today.For example, in the UK, USA and Canada, units are still used that do not have an integer decimal ratio with the metric system.

In 1960, the XI General Conference on Weights and Measures approved the International System of Units, abbreviated as SI (Systeme International d Unites), in Russian transcription - SI. In 1970, this system was supplemented by the seventh main PV - concentration of matter - mol. In 1980, SI was adopted in our country, it is regulated by GOST 8.417-81.

Classification of units of measurement of physical quantities

Units of measurement are one of the objects of the RF Law "On ensuring the uniformity of measurements". It contains the names of designations and the rules for writing units of quantities, as well as the rules for their application on the territory of the Russian Federation are established by the government of the Russian Federation, with the exception of cases provided for by acts of legislation of the Russian Federation.

The government may allow non-system units of values to be used on an equal basis with the units of the International System of Units. For example, in Russia, such non-systemic units of measurement are degrees Celsius and Kcal, along with Kelvin and joule.

Product characteristics and parameters; exported, including measuring instruments, can be expressed in units of values established by the customer.

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http://www.allbest.ru/

1. Subjects of metrology

metrology standard measurement

Subjects of metrology are legal entities and individuals engaged in metrological activities. These include international and regional metrology organizations, as well as metrological services (government and legal entities).

Metrological service - organizing and / or performing work and / or providing services to ensure the uniformity of measurements, a structural subdivision of the central office of the federal executive body and / or its territorial body, a legal entity or a structural subdivision of a legal entity or an association of legal entities, employees of a legal entity, individual entrepreneur .

There are three levels of subjects of metrology: international, regional and national (Fig. 1).

The international level is represented by international metrological organizations, which include representatives of national metrology organizations, and the regional level is represented by metrological organizations of the countries of a certain region of the globe. The national metrology level has two sublevels:

* state;

* services of legal entities.

The state sublevel of metrology includes Rostekhregulirovanie, scientific metrological centers (NMC) and centers of standardization and metrology (CSM). Each group of subjects of the national sub-level has specific functions and areas of competence.

Rostekhregulirovanie (Federal Service for Technical Regulation and Metrology) carries out state management of ensuring the uniformity of measurements. His competence includes:

* submission to the Government of the Russian Federation of proposals on the units of quantities allowed for use;

* establishment of rules for the creation, approval, storage and use of measurement standards of units of quantities;

* determination of general metrological requirements for instruments, methods and results of measurements;

* implementation of state metrological control and supervision,

* monitoring compliance with the terms of international treaties of the Russian Federation on the recognition of test results and verification of measuring instruments;

Rice. 1. Structure of subjects of metrology

CIPM - International Committee for Weights and Measures, BIPM - International Bureau of Weights and Measures, OIML - International Organization of Legal Metrology, ISO - International Organization for Standardization, TC - Technical Committee, GNMC - State Scientific Metrology Centers, RKS - - Russian Calibration Service, MSO - metrological service of industries, SME - metrological service of enterprises, CSM - center for standardization and metrology

* management of the activities of the State Metrological Service and other state services for ensuring the uniformity of measurements;

* participation in the activities of international organizations on ensuring the uniformity of measurements.

The State Metrological Service is under the jurisdiction of Rostekhregulirovanie and includes:

* state scientific metrological centers (GNMC);

* bodies of the State Metrological Service in the regions of Russia.

GNMCs are represented by the State Service for Time, Frequency and Determination of the Earth's Rotation Parameters (GSPP), the State Service for Standard Samples, Composition and Properties of Substances and Materials (GSSO) and the State Service for Standard Reference Data on Physical Constants and Properties of Substances and Materials (GSSSD). The management and coordination of their activities is carried out by Rostekhregulirovanie.

GNMC are responsible for the creation, improvement, storage and use of state measurement standards of units of quantities, as well as for the development of regulatory documents to ensure the uniformity of measurements

The bodies of the State Metrological Service include FMCs that carry out state metrological control and supervision in all regions of Russia.

The metrological service of legal entities is represented by the metrological services of federal governing bodies and enterprises (SMEs) that are legal entities (the Law on Ensuring the Uniformity of Measurements). Metrological services in state governing bodies and at enterprises are created, if necessary, in the prescribed manner to carry out work to ensure the uniformity and required accuracy of measurements, as well as to carry out metrological control and supervision. When performing work in areas where verification of measuring instruments is necessary, the creation of metrological services and other organizational structures to ensure the uniformity of measurements is mandatory.

Metrological services of legal entities carry out metrological control by calibrating measuring instruments, supervising the condition and use of measuring instruments, certified measurement techniques, standards of units of quantities used for calibrating measuring instruments, as well as observing the established metrological rules and norms. In addition, they check the timeliness of the submission of measuring instruments for testing in order to approve the type of measuring instruments, as well as for verification and calibration.

2. Means of verification and calibration

Measuring instruments used in the areas of state metrological control are subject to verification during release from production and repair, during import by import, during operation and sale.

Verification is the determination of the suitability of measuring instruments for use on the basis of experimentally determined metrological characteristics and control of their compliance with the established requirements.

Distinguish between state and departmental verification, as well as primary (when released from production, after repair, when imported from abroad) and periodically carried out at specified intervals. Periodic verifications are established based on the serviceability of the MI between verification. It is possible to carry out an extraordinary and inspection verification.

An extraordinary verification is carried out, regardless of the period of periodic verification, when it is necessary to make sure that the measuring instrument is in good working order. An extraordinary verification is carried out during the control of the verification process, if the verification mark is damaged.

Inspection verification is carried out during a metrological audit. Verification is carried out by the metrological service. Verification measurements are performed under normal conditions, which are regulated by GOST 8.395-80 - Normal conditions for verification. General requirements. Verification is one of the links in the transfer of the unit size from the standard to the working measuring instruments.

The body of the state metrological service conducts accreditation for the right to carry out verification. According to the decision of the state standard, the right of verification may be granted to other organizations, subject to their accreditation for the right to verification. The accreditation procedure is established by the state standard. Verification is carried out by persons certified as verifiers in the body of the state metrological service.

Verification is divided into 3 parts: metrological, technical and administrative. During metrological verification, establish:

the main error of the device;

stability, repeatability and drift;

sensitivity to electromagnetic interference, resolution of reading devices, etc.

During technical verification, the following is carried out: verification of the general condition of measuring instruments, detection of dirt, wear, correct installation of measuring instruments, assessment of the possibility of obtaining incorrect measurements due to deliberate misuse.

During administrative verification, the presence of a verification mark or a verification certificate, the date of the previous verification, the integrity of brands, locks and other devices, the availability of documents (verification protocols, repairs) are verified.

Initial verification is carried out in order to ensure the compliance of the introduced measuring instruments with the approved type. Subsequent verification is carried out in order to establish the suitability for use of measuring instruments in operation and to confirm or remove this status. Initial verification can be carried out on the premises of the manufacturer, user, body of the state metrological service or an independent organization. The place of verification is established by the manufacturer, dealer or user.

Initial verification can be carried out in stages, for example: part of the verification can be carried out before installation, and part after installation of the measuring instrument at the site of operation. As a rule, each copy of the SI is subject to primary verification. For the simplest measuring instruments produced by mass terrazh, selective verification is allowed. In case of positive results of selective verification, a verification mark is applied to all measuring instruments from the verified batch. Each sample of SI or the corresponding sample of a given set of SI shall undergo subsequent verification. Each SI is subject to periodic verification after a certain number of measurements since the last verification or at certain time intervals. The bodies of the state metrological service are obliged to take into account the results of subsequent verifications and develop recommendations for adjusting the calibration interval. The result is confirmation of the suitability of measuring instruments for use in areas subject to state metrological control, or recognition of measuring instruments as unsuitable. If the verification results are positive, a verification mark is applied to the measuring instrument and (or) a certificate is issued - a verification certificate. For unsuitable measuring instruments, the certificate and imprint of the verified stamp are canceled and a certificate of unsuitability is issued. Bodies of the state metrological service must ensure control of the verification process. During the control, the rules and methods of verification behavior, the personnel conducting the verification, standards and auxiliary equipment, calibration intervals, time and place of verification, etc. are checked.

Calibration of measuring instruments is a set of operations performed in order to determine and confirm the actual values of metrological characteristics and / or suitability for use of measuring instruments that are not subject to state metrological control and supervision. The suitability of a measuring instrument means the compliance of its metrological characteristics with previously established technical requirements, which may be contained in a regulatory document or determined by the customer. The conclusion about suitability is made by the calibration laboratory.

Calibration replaced the departmental verification and metrological certification of measuring instruments that previously existed in our country. Unlike verification, which is carried out by the bodies of the state metrological service, calibration can be carried out by any metrological service (or by an individual) if there are proper conditions for the qualified performance of this work. Calibration is a voluntary operation and can also be performed by the metrological service of the enterprise itself. This is another difference from verification, which, as already mentioned above, is mandatory and is subject to control by the authorities of the SMS.

However, the voluntary nature of calibration does not relieve the metrological service of the enterprise from the need to comply with certain requirements. The main one is traceability, i.e. obligatory "binding" of the working measuring instrument to the national (state) standard. Therefore, the calibration function should be considered as an integral part of the national traceability system. And if we consider that the principles of the national system for ensuring the uniformity of measurements are harmonized with international rules and norms, then calibration "is included in the global system for ensuring the uniformity of measurements.

Fulfillment of the specified requirement (“binding” to the standard) is also important from another point of view: measurements are an integral part of technological processes, i.e. they directly affect product quality. In this regard, the measurement results must be comparable, which is achieved only by transferring unit sizes from state standards and observing the rules and regulations of legal metrology. The credibility of the seller of products is backed up by certificates of calibration of measuring instruments issued on behalf of a reputable national metrological organization.

The introduction of calibration in Russia has its own characteristics. In Western countries, calibration work expanded and developed, growing out of the needs of increasing the competitiveness of products, and at the same time, a rather limited range of measuring instruments was subject to verification (as a mandatory function). In Russia, on the other hand, calibration is a product of the denationalization of the processes of control over the serviceability of instruments. And, consequently, the rejection of the general obligation of verification gave rise to the function of calibration. This process of liberalization of metrological control is not welcomed by everyone and does not go smoothly. Metrologists of both the State Metrological Service and the metrological services of enterprises have to move from the usual forms of interaction that have been worked out for decades to new relationships, which often causes a negative reaction.

The introduction of calibration is objectively hampered by the lack of competition. There is a certain contradiction here. On the one hand, in accordance with the law, enterprises have the right to independently organize the calibration of measuring instruments and are not interested (in the absence of competition) to be accredited by the competent accreditation bodies for the right to carry out calibration work. On the other hand, enterprises understand that isolation from the state system of transferring unit sizes from state standards according to an established scheme of working measuring instruments can lead to a loss of accuracy and reliability of measurement results.

The following options for organizing calibration work are possible:

the company independently organizes calibration work and is not accredited in any system;

an enterprise interested in increasing the competitiveness of products is accredited in the Russian Calibration System (RSK) for the right to carry out calibration work on behalf of the organization accrediting it;

the enterprise is accredited by the RSK for the purpose of performing calibration work on a commercial basis;

enterprises accredited for the right to calibrate measuring instruments simultaneously receive an accreditation certificate for the right to carry out calibration work on the same types (areas) of measurements;

metrological institutes and bodies of the State Metrological Service are registered with RSK both as accreditation bodies and as calibration organizations;

accreditation of the enterprise as a calibration laboratory in a foreign open-type calibration service.

To date, the preferred options for organizing the calibration business in Russia have not yet been determined. But we can already talk about the principles of organizing the RSK. The Russian calibration system is based on such principles as voluntary membership; obligatory transfer of unit sizes from state standards to working measuring instruments; professionalism and technical competence of DGC subjects; self-sufficiency.

The standard of a unit of a physical quantity is a measuring instrument or a complex of measuring instruments intended for reproducing and storing units and transferring its size to a measuring instrument below the calibration scheme and approved as a standard in the prescribed manner.

The primary standard is a standard that reproduces a unit of a physical quantity with the highest accuracy possible in a given field of measurements at the modern level of scientific and technical achievements. The primary standard can be national (state) and international.

The national standard is approved as a reference instrument for the country by the national metrology body. In Russia, national (state) standards are approved by the State Standard of the Russian Federation.

International measurement standards are stored and maintained by the International Bureau of Weights and Measures (BIPM). The most important task of the BIPM activity is systematic international comparisons of national standards of the largest metrological laboratories of different countries with international standards, as well as among themselves, which is necessary to ensure the reliability, accuracy and uniformity of measurements as one of the conditions of international economic relations. Both the standards of the basic quantities of the SI system and derivatives are subject to comparison. Certain comparison periods have been established. For example, the standards of the meter and the kilogram are compared every 25 years, and the electrical and light standards are compared once every 3 years.

Secondary and working (bit) standards are subordinated to the primary standard. The size of the reproduced unit by the secondary standard is compared with the state standard. Secondary standards (they are sometimes called "copy standards") can be approved either by the State Standard of the Russian Federation, or by state scientific metrological centers, which is associated with the peculiarities of their use. Working standards perceive the size of a unit from secondary standards and, in turn, serve to transfer the size to a less accurate working standard (or a standard of a lower grade) and working measuring instruments.

Calibration chart for measuring instruments is a regulatory document establishing the subordination of measuring instruments involved in the transfer of the unit size from the standard to working measuring instruments (indicating the methods and errors in the transfer).

To ensure the correct transfer of the sizes of units of measurement from the standard to the working measuring instruments, verification diagrams are drawn up that establish the metrological subordination of the state standard, bit standards and working measuring instruments.

Verification schemes are divided into state and local. State verification diagrams apply to all measuring instruments of this type used in the country. Local verification schemes are intended for the metrological bodies of ministries, they also apply to measuring instruments of subordinate enterprises. In addition, a local scheme can be drawn up for measuring instruments used at a particular enterprise. All local verification schemes must comply with the subordination requirements, which are determined by the state verification scheme (Fig. 31.2). State calibration charts are developed by research institutes of the State Standard of the Russian Federation, holders of state standards.

In some cases, it is impossible to reproduce the entire range of values with one standard, therefore, several primary standards may be provided in the scheme, which together reproduce the entire measurement scale. For example, the temperature scale from 1.5 to 1 * 105 K is reproduced by two state standards.

State calibration schemes are approved by the State Standard of the Russian Federation, and local ones - by departmental metrological services or the management of the enterprise.

Let us consider in general terms the content of the state verification scheme.

The names of standards and working measuring instruments are usually placed in rectangles (for the state standard, a double-circuit rectangle). The metrological characteristics for this stage of the scheme are also indicated here. In the lower part of the diagram, there are working measuring instruments, which, depending on their degree of accuracy (ie, measurement errors), are divided into five categories: the highest accuracy; highest precision; high precision; medium accuracy; inferior accuracy. The highest accuracy is usually commensurate with the degree of error of the state standard measuring instrument. In each step of the verification scheme, the procedure (method) for transferring the unit size is regulated. The names of the verification (calibration) methods are located in ovals, which also indicate the permissible error of the verification (calibration) method. The main indicator of the reliability of the transmission of the size of the unit of magnitude is the ratio of the errors of measuring instruments between the higher and lower stages of the verification scheme. Ideally, this ratio should be 1:10, but in practice it cannot be achieved, and the minimum acceptable ratio is considered to be 1: 3. The greater the value of this ratio, the less confidence in the reliability of the readings of the measuring device.

When developing specific verification charts, it is necessary to follow the diagram below. Strict adherence to verification schemes and timely verification of discharge standards are necessary conditions for the transfer of reliable dimensions of units of measurement to working measuring instruments.

Posted on Allbest.ru

...Similar documents

The history of the development of metrology. Legal foundations of metrological activity in the Russian Federation. Legal liability for violation of regulatory requirements. Objects, measurement methods, types of control. International system of units of physical quantities.

cheat sheet added on 11/13/2008

Legal foundations of metrological assurance of the uniformity of measurements. The system of standards of units of physical quantities. State services for metrology and standardization in the Russian Federation. Activities of the Federal Agency for Technical Regulation and Metrology.

term paper added on 04/06/2015

Theoretical foundations and main concepts of metrology. Methods for standardizing the metrological characteristics of measuring instruments, assessing the errors of instruments and measurement results. Basics of ensuring the uniformity of measurements. The structure and functions of metrological services.

tutorial, added 11/30/2010

Subject and main objectives of theoretical, applied and legal metrology. Historically important milestones in the development of measurement science. Characteristics of the international system of units of physical quantities. Activities of the International Committee for Weights and Measures.

abstract added on 10/06/2013

Regulation and control by the state of a number of provisions of metrology. State system for ensuring the uniformity of measurements. Subjects of metrology. Management of three government reference services. Voluntary and mandatory certification.

test, added 01/21/2009

Metrological support of construction. A system for the development, putting into production and putting into circulation of measuring instruments that ensure the determination of product characteristics with the required accuracy. The current state of metrology in construction.

abstract, added 09/16/2013

General provisions of the State system for ensuring the uniformity of measurements. Transfer of sizes of units of physical quantities, their verification schemes. Methods for verifying measuring instruments. Errors of state primary and special standards, their assessment.

test, added 09/19/2015

Basic information about physical quantities, their standards. System of international units, classification of types and measuring instruments. Quantitative estimates of the error. Measurement of voltage and current. Purpose of voltmeter, oscilloscope and digital frequency meter.

cheat sheet, added 06/14/2012

Basics, goals, objectives and functions of standardization. Categories and types of standards, the order of their development. Bodies and services for standardization. Metrological concepts. Measurement classification. The role of metrology. Certification issues in the laws of the Russian Federation.

abstract, added 01/09/2009

The main activities of legal metrology, areas of application of its rules. The content and objectives of the Federal Law "On ensuring the uniformity of measurements". Legal bases and principles of standardization. Directions of state policy in this area.

Subjects of metrology - legal entities and individuals carrying out metrological activities These include international and regional organizations in metrology, as well as metrological services (government and legal entities).

Metrological service - organizing and / or performing work and / or providing services to ensure the uniformity of measurements, a structural subdivision of the central office of the federal executive body and / or its territorial body, a legal entity or a structural subdivision of a legal entity or an association of legal entities, employees of a legal entity, individual businessman .

There are three levels of subjects of metrology: international, regional and national (Fig. 2.4).

International level represented by international metrological organizations, which include representatives of national metrology organizations, and regional- metrological organizations of the countries of a certain region of the globe. National level metrology has two sublevels:

State;

Services of legal entities.

The state sublevel of metrology includes Rostekhregulirovanie, scientific metrological centers (NMC) and centers of standardization and metrology (CSM). Each group of subjects of the national sub-level has specific functions and areas of competence.

Rostekhregulirovanie(Federal Service for Technical Regulation and Metrology) carries out state management of ensuring the uniformity of measurements. His competence includes:

Submission to the Government of the Russian Federation of proposals on units of quantities allowed for use;

Establishment of rules for the creation, approval, storage and use of measurement standards of units of quantities;

Determination of general metrological requirements for instruments, methods and results of measurements;

Implementation of state metrological control and supervision,

Monitoring compliance with the terms of international treaties of the Russian Federation on the recognition of test results and verification of measuring instruments;

CIPM - International Committee for Weights and Measures, BIPM - International Bureau of Weights and Measures, OIML - International Organization of Legal Metrology, ISO - International Organization for Standardization, TC - Technical Committee, GNMC - State Scientific Metrology Centers, RKS - Russian Calibration Service, IES - metrological service of industries, SME - metrological service of enterprises, CSM - center for standardization and metrology

Management of the activities of the State Metrological Service and other state services for ensuring the uniformity of measurements;

Participation in the activities of international organizations on ensuring the uniformity of measurements.

State Metrological Service is under the jurisdiction of Rostekhregulirovanie and includes:

State Scientific Metrological Centers (GNMC);

Bodies of the State Metrological Service in the regions of Russia.

GNMC presented by the State Service for Time, Frequency and Determination of the Earth's Rotation Parameters (GSSVCH), the State Service for Standard Samples, Composition and Properties of Substances and Materials (GSSO) and the State Service for Standard Reference Data on Physical Constants and Properties of Substances and Materials (GSSSD). The management and coordination of their activities is carried out by Rostekhregulirovanie.

GNMC are responsible for the creation, improvement, storage and use of state measurement standards of units of quantities, as well as for the development of regulatory documents to ensure the uniformity of measurements

The bodies of the State Metrological Service include FMCs that carry out state metrological control and supervision in all regions of Russia.

Metrological service of legal entities represented by the metrological services of federal government bodies and enterprises (SMEs) that are legal entities (Law on Ensuring the Uniformity of Measurements). Metrological services in state governing bodies and at enterprises are created, if necessary, in the prescribed manner to carry out work to ensure the uniformity and required accuracy of measurements, as well as to carry out metrological control and supervision. When performing work in areas where verification of measuring instruments is necessary, the creation of metrological services and other organizational structures to ensure the uniformity of measurements is mandatory.

Metrological services of legal entities carry out metrological control by calibrating measuring instruments, monitoring the condition and use of measuring instruments, certified measurement techniques, standards of units of quantities used for calibrating measuring instruments, as well as observing the established metrological rules and norms. In addition, they check the timeliness of the submission of measuring instruments for testing in order to approve the type of measuring instruments, as well as for verification and calibration.

Physical quantities are the object of metrology. The concept of "physical quantity" in metrology, as in physics, is understood as a property of physical objects (systems), qualitatively common to many objects, but quantitatively individual for each object, that is, a property that can be for one object in one or another number of times more or less than for another (for example, length, mass, density, temperature, force, speed). The quantitative content of the property corresponding to the concept of "physical quantity" in a given object is the size of the physical quantity.

The totality of quantities, interconnected by dependencies, forms a system of physical quantities. Objectively existing relationships between physical quantities are represented by a number of independent equations. The number of equations m is always less than the number of quantities n. Therefore, m values of a given system are determined through other values, and n - m values - independently of others. The latter quantities are usually called basic physical quantities, and the rest are called derived physical quantities.

The presence of a number of systems of units of physical quantities, as well as a significant number of non-systemic units, the inconvenience associated with recalculation during the transition from one system of units to another, required the unification of units of measurement. The growth of scientific, technical and economic ties between different countries necessitated such unification on an international scale.

A unified system of units of physical quantities was required, practically convenient and covering various areas of measurement. At the same time, it had to preserve the principle of coherence (equality to unity of the coefficient of proportionality in the equations of communication between physical quantities).

In Russia, GOST 8.417-2002 is in force, which prescribes the mandatory use of SI. It lists the units of measurement, lists their Russian and international names and establishes the rules for their use. According to these rules, only international symbols may be used in international documents and on instrument scales. In internal documents and publications, you can use either international or Russian designations (but not both at the same time).

Derived units of the International System of Units are formed using the simplest equations between quantities, in which the numerical coefficients are equal to one. So, for the linear speed, as the governing equation, you can use the expression for the speed of uniform motion v = l / t.

With the length of the traveled path (in meters) and time t, for which the distance traveled (in seconds), the speed is expressed in meters per second (m / s). Therefore, the SI unit of speed - meter per second - is the speed of a rectilinear and uniformly moving point at which it is in time t s moves at a distance of 1 m.

Subjects of metrology:

- state metrological service;

- metrological services of federal executive authorities and legal entities;

- metrological organizations.

41. Definition, types and methods of measurements

Measurement- this is the finding of the value of a physical quantity empirically with the help of special technical means, called measuring instruments. The resulting information is called measurement information.

Measurements are based on certain principles. Measuring principle Is a collection of physical phenomena on which measurements are based. The set of techniques for using principles and measuring instruments is defined as a measurement method. The measurement method is the main characteristic of specific measurements. There are two main methods of measurement: the direct assessment method and the comparison method.

Direct assessment method- a measurement method in which the value of a quantity is determined directly from the reading device of a direct-acting measuring device. In scientific and technical documentation and literature, this method is sometimes called the direct transformation method.

Comparison method- a measurement method in which the measured quantity is compared with the quantity reproduced by the standard. The comparison method is implemented in practice in the form of the following modifications: the zero method, in which the resulting effect of the influence of the values on the comparison device is brought to zero (it is also called compensatory); differential method, in which the difference between the measured and the known value reproduced by the measure is formed and measured; the method of coincidence, in which the difference between the measured value and the value reproduced by the measure is measured using the coincidence of the marks of the scales or periodic signals; the method of opposition, in which the measured value and the value reproduced by the measure simultaneously act on the comparison device, with the help of which the relationship between these values is established. Basic properties of the measurement state:

- accuracy of measurement results;

- reproducibility of measurement results;

- the convergence of the measurement results;

- speed of obtaining results;

- uniformity of measurements.

In this case, the reproducibility of measurement results is understood as the proximity of the measurement results of the same quantity obtained in different places, by different methods, by different means, by different operators, at different times, however, under the same measurement conditions (temperature, pressure, humidity, etc. etc.).

The convergence of the measurement results is the closeness of the results of measurements of the same quantity, carried out repeatedly using the same means, by the same method under the same conditions and with the same thoroughness.

Measurement is a mapping from an empirical system to a number system that preserves the order of relationships between objects. The classical concept of measurement as a way of assigning variable values to objects is called grading. The mapping of the object property to the scale is carried out here in conventional units.

The actual measurement requires the determination of the unit - the standard of the scale. In this case, only spatial and temporal characteristics can be measured, as well as the number - additive values. However, in the social and behavioral sciences, a broader view of measurement as the assignment of values to objects in accordance with a given system of relations at various levels has gained recognition.